Cleanroom

Clean room is also called dust-free room or cleansing room,is now an indispensable important environment of semiconductor, precision manufacturing, liquid crystal manufacturing, optical fabrication, circuit board manufacturing and bio chemical, pharmaceutical, food industries. In recent years, due to the innovation and development of technology, the demand for high precision,fine small size is more and more urgent,such as ultra large scale integrated circuit research & manufacturing,has become a worldwide important project in the development of science and technology, and our company' s design idea and the construction technology are in a leading position in the industry.

Design Basis

《國際標準ISO/DIS14644》、《藥品生產質量管理規范》GMP2010、《潔凈廠房設計規范》GB50070-2001 、《潔凈室施工及驗收規范》GB50591-2010、

《醫藥工業潔凈廠房設計規定》GB50457-2008 、《通風與空調工程施工及驗收規范》GB50738-2011

Cleanroom project is a very broad application of the basic supporting industries, applied in Medical, Electronic Information, Biological Engineering, Food, Precision Instruments,Aerospace, Petroleum, Fine Chemical, Automobile Manufacturing and other industries, and according to the requirements of the industry precision and clean, the cleanroom's level has also a big difference.

美國聯邦標準FS209E 中的潔凈等級

| 等級名稱 | 等級限制 | ||||||||||

| 0.1μm ( 微米) | 0.2μm ( 微米) | 0.3μm ( 微米) | 0.5μm ( 微米) | 5μm ( 微米) | |||||||

| 國際 | 英制 | m3 | Ft3 | m3 | Ft3 | m3 | Ft3 | m3 | Ft3 | m3 | Ft3 |

| M1.0 | 350 | 99.1 | 75.7 | 2.14 | 30.9 | 0.875 | 10 | 0.283 | / | / | |

| M1.5 | 1 | 1240 | 35.0 | 265.0 | 7.5 | 106 | 3 | 35.3 | 1 | / | / |

| M2.0 | 3500 | 99.1 | 757 | 21.4 | 309 | 8.75 | 100 | 2.83 | / | ||

| M2.5 | 10 | 12400 | 350.0 | 2650 | 75 | 1060 | 30 | 353 | 10 | / | / |

| M3.0 | 35000 | 991.0 | 7570 | 214 | 309 | 87.5 | 1000 | 28.3 | / | / | |

| M3.5 | 100 | / | / | 26500 | 750 | 10600 | 300 | 3530 | 100 | / | / |

| M4.0 | / | / | 75700 | 2140 | 30900 | 875 | 10000 | 283 | / | / | |

| M4.5 | 1000 | / | / | / | / | / | / | 35300 | 1000 | 247 | 7 |

| M5.0 | / | / | / | / | / | / | 100000 | 2830 | 618 | 17.5 | |

| M5.5 | 10000 | / | / | / | / | / | / | 353000 | 10000 | 2470 | 70 |

| M6.0 | / | / | / | / | / | / | 1000000 | 28300 | 6180 | 175 | |

| M6.5 | 100000 | / | / | / | / | / | / | 3530000 | 100000 | 24700 | 700 |

| M7.0 | / | / | / | / | / | / | 10000000 | 283000 | 61800 | 1750 | |

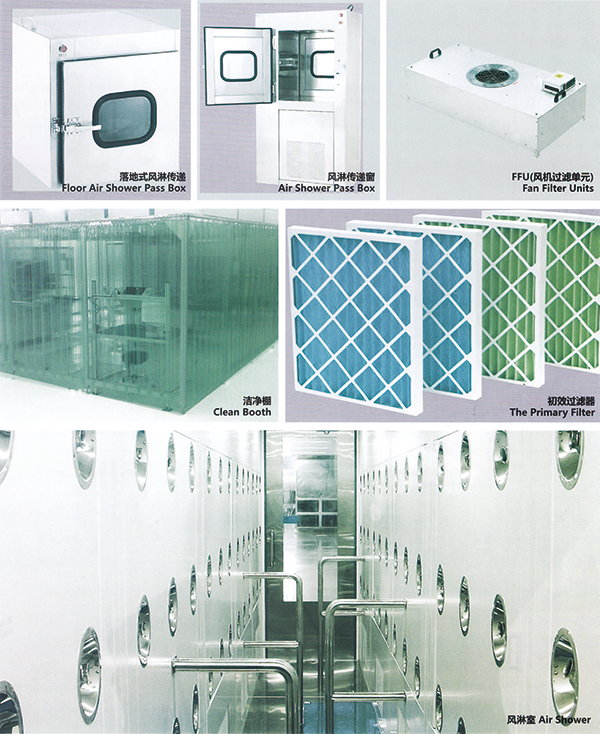

Air Filter

According to its working principle, air filter can be divided into the types of the primary filter, medium efficiency filter, and high efficiency filter.

According to the specific requirements of the project selection of different products, can be customized.

Air Shower

The microcomputer automatic control system, double door electronic interlocking;

The modular production, installation is simple, can shorten the project time;

The filtration efficiency of 99.99%@0.3μm;

Can be customized;

Fan Filter Units

FFU is the terminal of a modular power,with a filtration efficiency of the air supply device

Feature:Multi - blade Fan ; Simple circuit and control; Beautiful and light; Humanized design; Diversified configuration; Performance improvement;

Clean Booth

Frame: The aluminum industry (Stainless steel, iron pipe spray),pretty and steady;

The use of anti-static curtain, good antistatic effect, toughness is good, not easy ageing;

Centrifugal fan, low noise, long working life;

Purification level can reach 100-10000;